Genesis Coupe engine build

#1

http://www.hyundaiaftermarket.org/images/vendor1.png

Thread Starter

Join Date: Jun 2011

Location: NJ

Posts: 198

Likes: 0

Received 0 Likes

on

0 Posts

Vehicle: Hyundai Genesis 2.0T

Just reposting this thread over here from Gencoupe incase anything happens. Lots of good info I think.

Original Poster: Pavel_Engines

Original Poster: Pavel_Engines

This is a Hyundai Genesis Coupe engine build I recently completed. As of right now, there are very few performance parts available for the engine. Although the Hyundai Theta 2.0 engine is very similar to the Mitsubishi 4B11T, the only parts that directly cross over are ARP head studs and head gaskets. Engine bearings and connecting rods are different in size and will not work even with extensive modification to either part. Below is a description of the work performed on the engine and part used, both stock and aftermarket. Enjoy!

Engine parts list:

1. Manley 86.5mm forged pistons

2. K1 Technologies steel connecting rods, come with ARP 2000 rod bolts

3. ACL main and rod bearings custom made for application

4. OEM thrust bearings

5. ARP main studs, custom made for application

6. ARP head stud kit, 4B11T part

7. Cosworth 87mm bore, 1.1mm thick head gasket

Engine machine work performed:

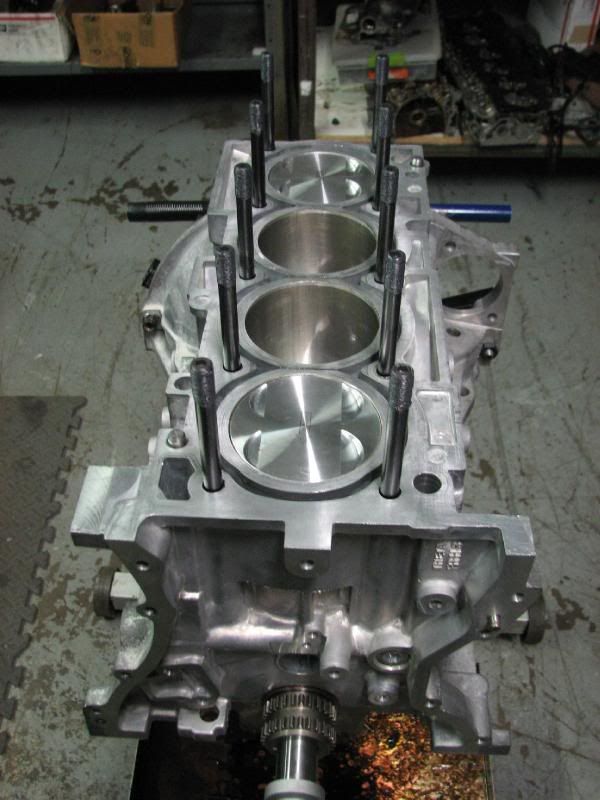

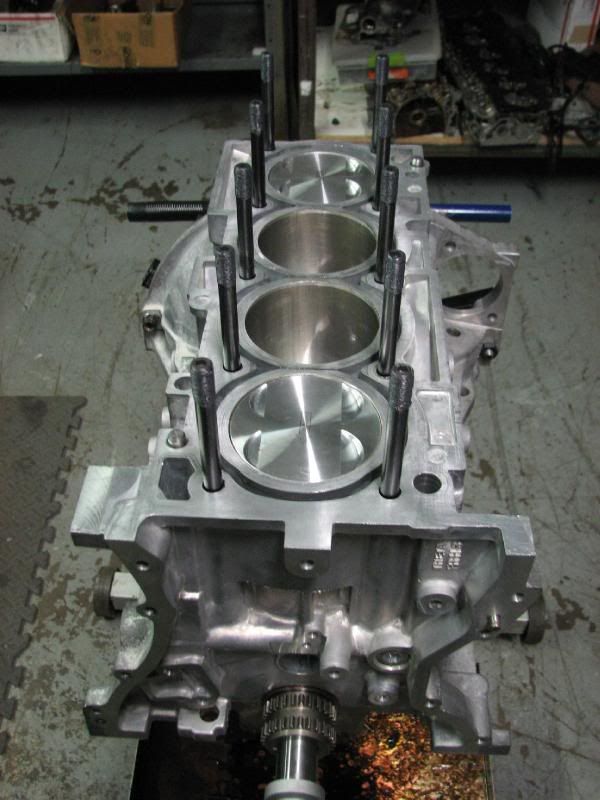

1. Block bore/hone to 86.5mm

2. Block align hone with ARP main studs

3. Balance and polish crankshaft

4. Weight match rods and pistons

5. Hand stone block and cylinder head mating surfaces

6. Inspect cylinder head, hand-lap valves, and check seal

Engine component review:

•Block- Cylinder block is aluminum construction, die cast, open deck design. Not the best for performance. Mitsubishi 4B11T block is a semi closed deck design with reinforcement at the cylinder head mating surface. This Hyundai block can greatly benefit from a flanged sleeve or a Honda-style girdle to prevent cylinders from walking and distorting under high cylinder pressure condition. Hyundai Theta block utilizes 2 bolt main caps, while Mitsubishi 4B11T utilizes 4 bolt main caps. Piston cooling jets fed from the main oil gallery spray oil on the intake side of the piston.

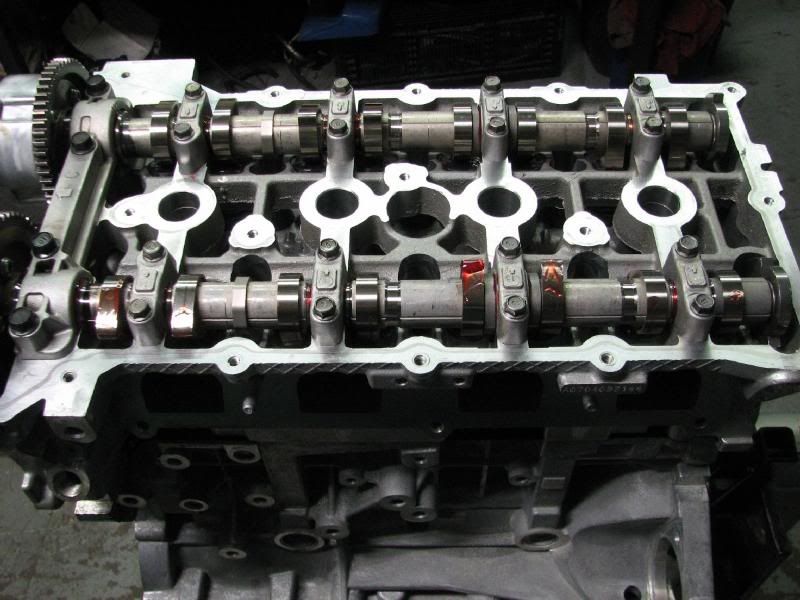

•Cylinder head- Excellent design of the head. Direct bucket over valve design unlike 4G63 which was a roller rocker design. 4B11T uses very thin 5.5mm stems on the intake and exhaust valves. 4G63 used 6.5mm stems on intake and exhaust. 4B11T uses very light weight shimless buckets. Intake and exhaust camshaft use an oil pressure controlled vain-type variable valve control system. Early 4G63 had no MIVEC system and late 4G63 only had MIVEC on intake camshaft. 4B11T camshafts are chain driven versus belt drive of the 4G63. Single valve springs utilized in the 4B11T.

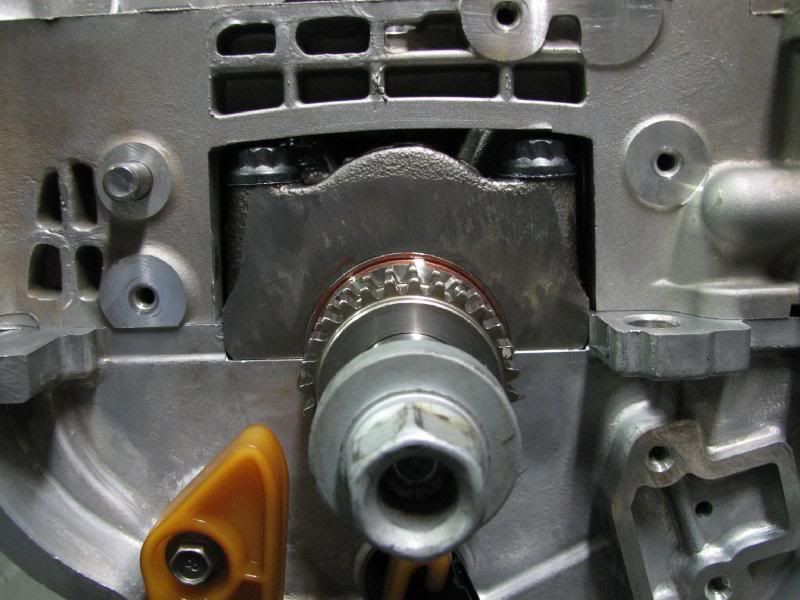

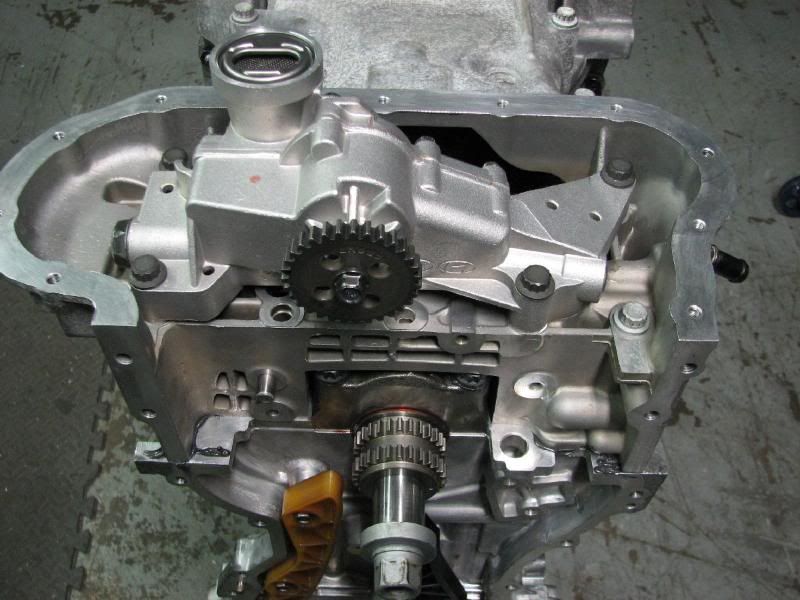

•Oil pump- Oil pump is mounted on the bottom of the upper oil pan girdle and chain driven off the front of the crankshaft. Oil pump is a gear-rotor design with a single stage for pressure. 4G63 used a spur gear style oil pump driven by the timing belt as an auxiliary item.

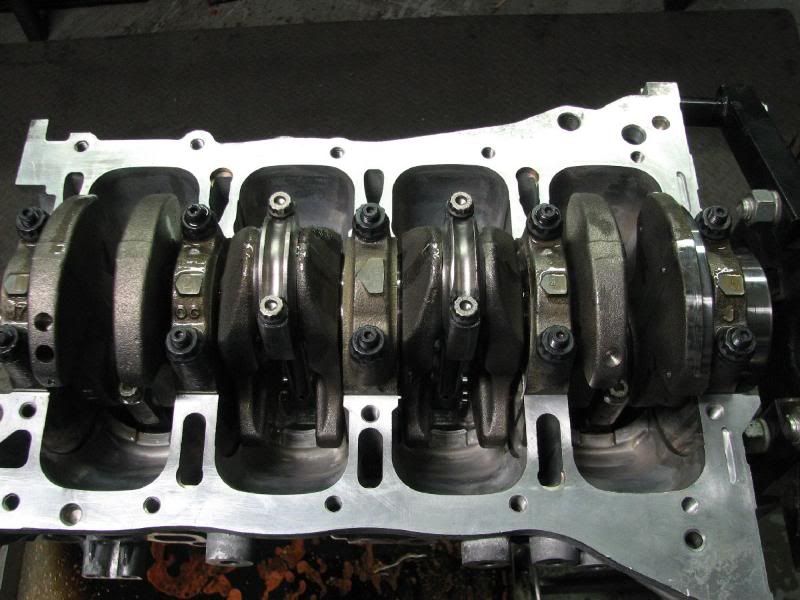

•Crankshaft- Crankshaft is forged. It uses smaller rod and main journals than the EVO 10 4B11T version. Rear of the crankshaft has provision for crankshaft position reluctor wheel, which is used by the Mitsubishi 4B11T. Hyundai engine uses the flywheel for crankshaft position. Since the rear of the crankshaft has provisions for the timing sprocket but does not use it, the crankshaft is actually out of balance. The front of the crankshaft was within 2 grams, while the rear was off by 10.5g. This required extensive drilling of the counterweight to correct out of balance. This out of balance can be detrimental to engine bearing life due to crankshaft flex at high engine rpm.

•Connecting rods- Hyundai engine uses powder steel metallurgy connecting rods. This is a cheap and effective way of production line manufacturing and adequate for the horsepower requirement of a stock factory engine. This type of connecting rod is not adequate for increased horsepower and high rpm engine. Powder steel metallurgy connecting rods usually fail catastrophically in a fracture fashion. Mitsubishi 4B11T engine uses forged steel connecting rods.

•Pistons- Pistons are cast aluminum using thin, performance-style rings. Stock pistons use a Teflon type of friction coating on the skirts.

•Gaskets- Stock head gasket is a multi layer steel design using 3 layers. Exhaust manifold gasket is a multi layer stainless steel design. Intake manifold gasket is a single layer metal design.

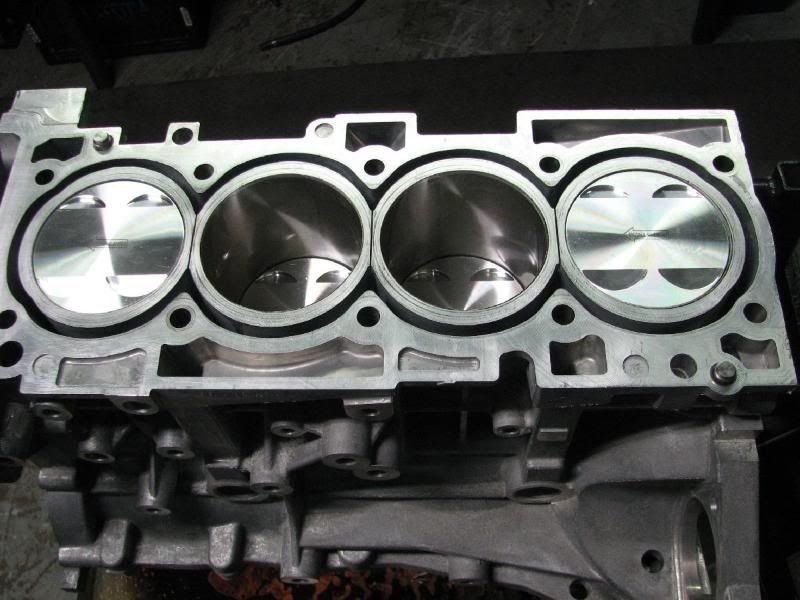

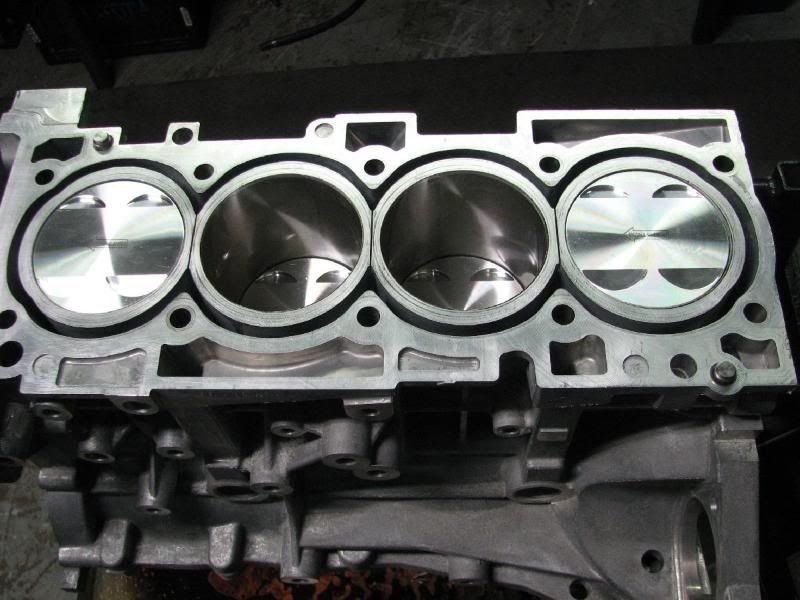

Engine block cylinders bored/honed to 86.5mm size and crankshaft main journals align honed with ARP main studs. Custom ARP main stud kit was made for this application. Four of the ten main studs were shortened to clear the upper oil pan.

Crankshaft polished and balance. Connecting rods and pistons weight matched. Manley pistons specification sheet stated piston weight between 333 to 334 grams. Piston weight measured on the precision scale read between 334.0 to 334.7 grams. All pistons were matched in weight. All pistons weight-matched to within 0.1 grams.

Connecting rods from K1 Technologies, a partner of Wiseco, are made in China similar to Eagle rods and use the same ARP 2000 3/8” thread 1.600” length bolts. All connecting rod weights were checked on the small and big end using a precision connecting rod scale. After confirming weights, the rods were matched on the small and big end, and confirmed as a whole. All connecting rod were weight-matched to within 0.1 grams.

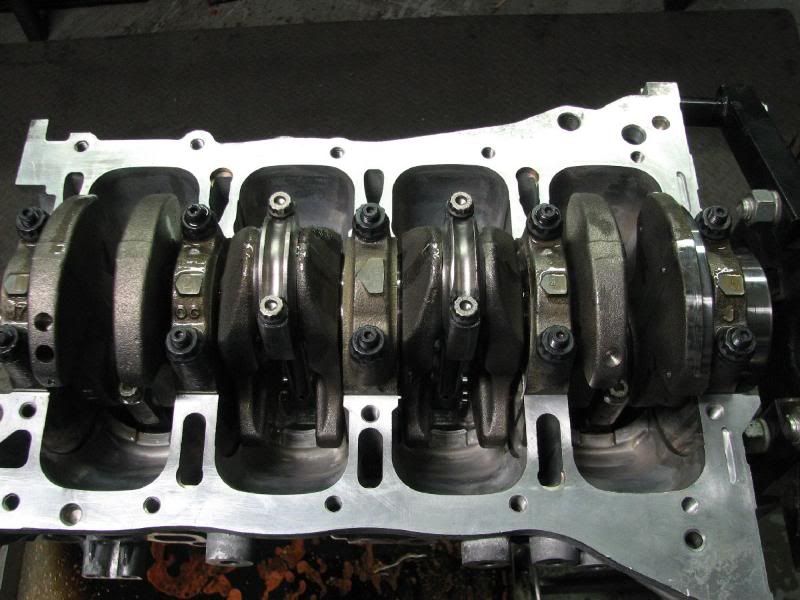

Polished and balanced crankshaft, Manley forged pistons, K1 Tech rods with bolts, and ACL performance rod bearings.

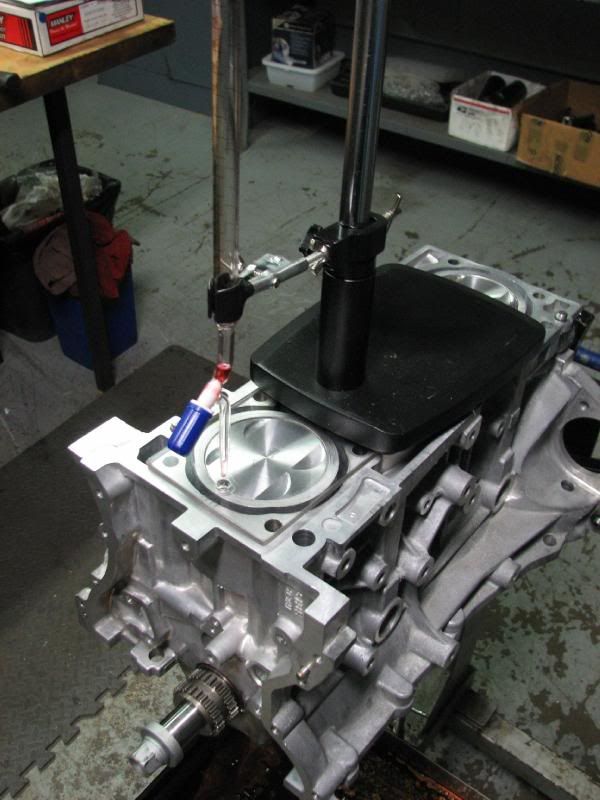

Piston ring gap verification is performed by installing a piston ring square to the bore and evenly lowering the ring below the deck surface. I made my own “tool” to do so. Some people use the piston itself, which works fine, but this is a faster positive way to do it.

Each connecting rod bolt is labeled using an engraver. Each bolt is measured and its length is recorded. During engine rebuild process connecting rod bolt length is recorded and compared to previous notes made. If connecting rod bolt length changes by more than 0.001” inch, then the bolt requires replacement. Connecting rod bolt is the most stressed component in the engine. Monitoring its size and condition can mean a difference between replacement of a $6 bolt or catastrophic engine failure.

Pistons installed

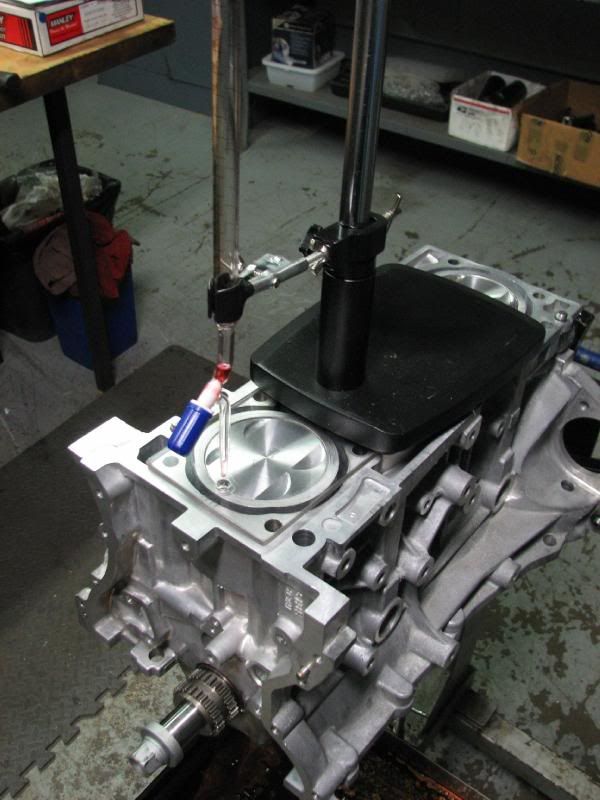

Connecting rod bolts tightened using a rod bolt stretch gauge. This is the most accurate method of tightening bolts. This method does not require any special lubricant. Stretch is a state that is measured via the dial indicator. This is more accurate than a torque method because torque method measures the friction in the thread. If improper lubricant is used then reading will not be accurate.

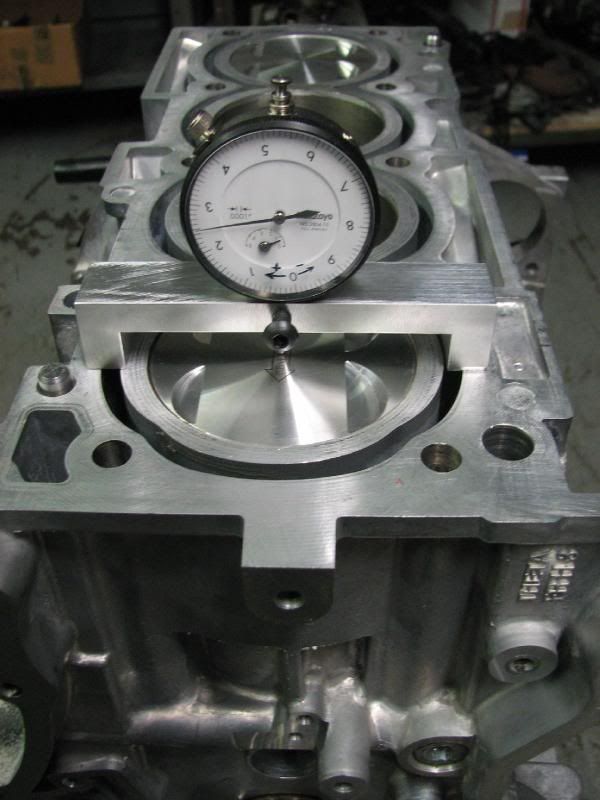

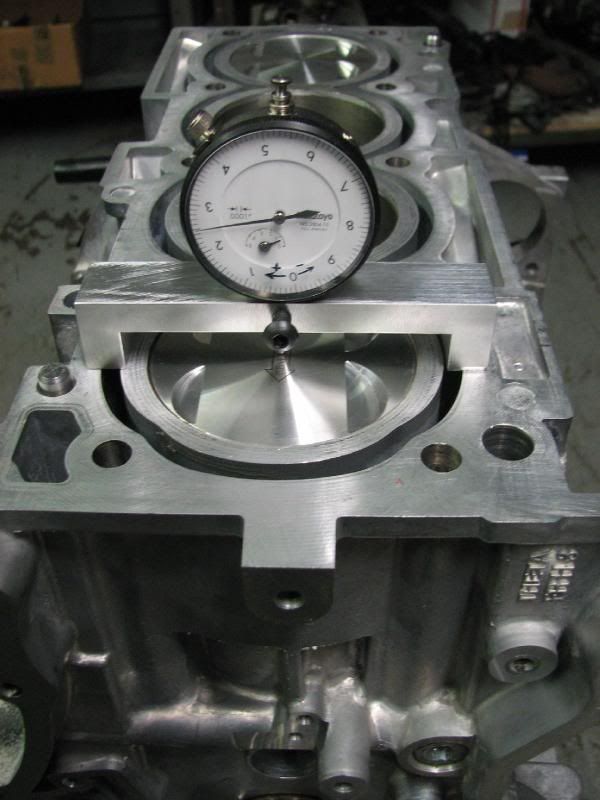

Cylinder 1 TDC is found using a bridge with a Mitutoyo dial indicator that reads in 0.0001” inch accuracy.

After TDC is established the piston dish volume can be measured. A clear acrylic plate is placed over the cylinder and a precision volume burette with colored alcohol fluid used to check piston dish volume.

ARP cylinder head stud kit installed into the block using ARP Ultra Torque moly lube.

Cosworth 87mm bore, 1.1mm thick headgasket installed

Cylinder head installed

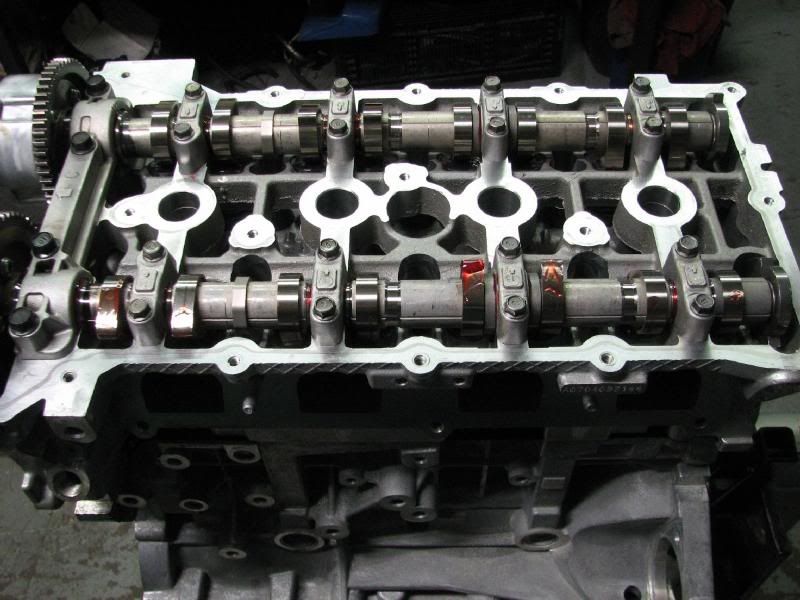

Camshafts and timing chain guides installed. Camshaft lobes covered in Clevite assembly lubricant.

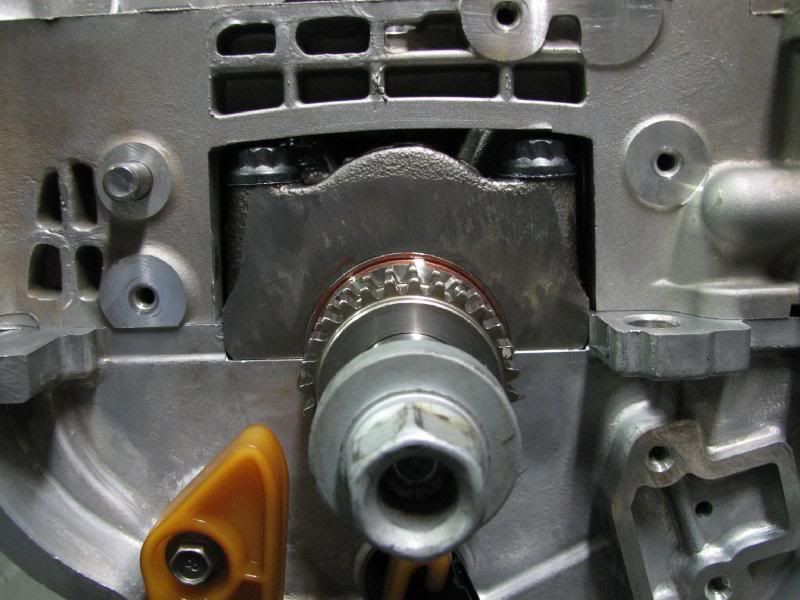

Comparison of standard and modified main studs

This is how close the modified stud comes to the upper oil pan. Unmodified stud does not allow the upper oil pan to seal the block.

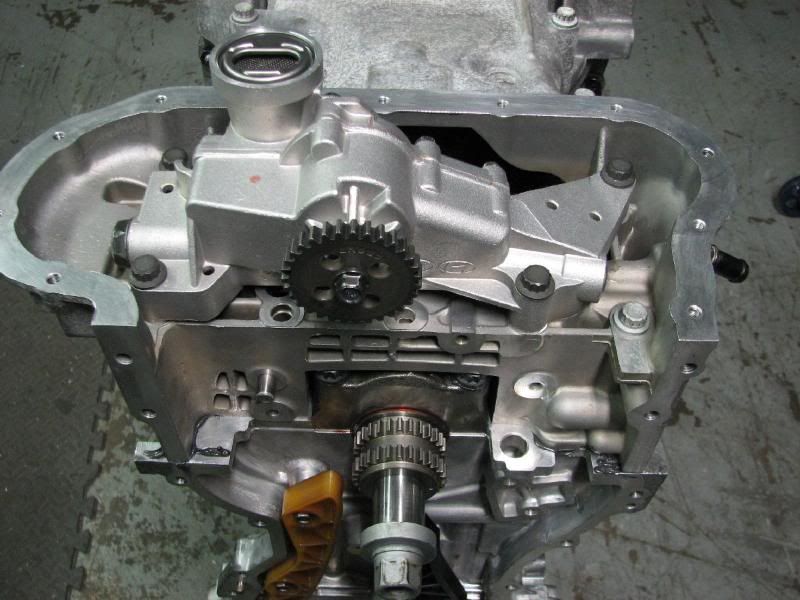

Oil pump, oil pump chain, and tensioner guides installed.

Complete long block.

Engine parts list:

1. Manley 86.5mm forged pistons

2. K1 Technologies steel connecting rods, come with ARP 2000 rod bolts

3. ACL main and rod bearings custom made for application

4. OEM thrust bearings

5. ARP main studs, custom made for application

6. ARP head stud kit, 4B11T part

7. Cosworth 87mm bore, 1.1mm thick head gasket

Engine machine work performed:

1. Block bore/hone to 86.5mm

2. Block align hone with ARP main studs

3. Balance and polish crankshaft

4. Weight match rods and pistons

5. Hand stone block and cylinder head mating surfaces

6. Inspect cylinder head, hand-lap valves, and check seal

Engine component review:

•Block- Cylinder block is aluminum construction, die cast, open deck design. Not the best for performance. Mitsubishi 4B11T block is a semi closed deck design with reinforcement at the cylinder head mating surface. This Hyundai block can greatly benefit from a flanged sleeve or a Honda-style girdle to prevent cylinders from walking and distorting under high cylinder pressure condition. Hyundai Theta block utilizes 2 bolt main caps, while Mitsubishi 4B11T utilizes 4 bolt main caps. Piston cooling jets fed from the main oil gallery spray oil on the intake side of the piston.

•Cylinder head- Excellent design of the head. Direct bucket over valve design unlike 4G63 which was a roller rocker design. 4B11T uses very thin 5.5mm stems on the intake and exhaust valves. 4G63 used 6.5mm stems on intake and exhaust. 4B11T uses very light weight shimless buckets. Intake and exhaust camshaft use an oil pressure controlled vain-type variable valve control system. Early 4G63 had no MIVEC system and late 4G63 only had MIVEC on intake camshaft. 4B11T camshafts are chain driven versus belt drive of the 4G63. Single valve springs utilized in the 4B11T.

•Oil pump- Oil pump is mounted on the bottom of the upper oil pan girdle and chain driven off the front of the crankshaft. Oil pump is a gear-rotor design with a single stage for pressure. 4G63 used a spur gear style oil pump driven by the timing belt as an auxiliary item.

•Crankshaft- Crankshaft is forged. It uses smaller rod and main journals than the EVO 10 4B11T version. Rear of the crankshaft has provision for crankshaft position reluctor wheel, which is used by the Mitsubishi 4B11T. Hyundai engine uses the flywheel for crankshaft position. Since the rear of the crankshaft has provisions for the timing sprocket but does not use it, the crankshaft is actually out of balance. The front of the crankshaft was within 2 grams, while the rear was off by 10.5g. This required extensive drilling of the counterweight to correct out of balance. This out of balance can be detrimental to engine bearing life due to crankshaft flex at high engine rpm.

•Connecting rods- Hyundai engine uses powder steel metallurgy connecting rods. This is a cheap and effective way of production line manufacturing and adequate for the horsepower requirement of a stock factory engine. This type of connecting rod is not adequate for increased horsepower and high rpm engine. Powder steel metallurgy connecting rods usually fail catastrophically in a fracture fashion. Mitsubishi 4B11T engine uses forged steel connecting rods.

•Pistons- Pistons are cast aluminum using thin, performance-style rings. Stock pistons use a Teflon type of friction coating on the skirts.

•Gaskets- Stock head gasket is a multi layer steel design using 3 layers. Exhaust manifold gasket is a multi layer stainless steel design. Intake manifold gasket is a single layer metal design.

Engine block cylinders bored/honed to 86.5mm size and crankshaft main journals align honed with ARP main studs. Custom ARP main stud kit was made for this application. Four of the ten main studs were shortened to clear the upper oil pan.

Crankshaft polished and balance. Connecting rods and pistons weight matched. Manley pistons specification sheet stated piston weight between 333 to 334 grams. Piston weight measured on the precision scale read between 334.0 to 334.7 grams. All pistons were matched in weight. All pistons weight-matched to within 0.1 grams.

Connecting rods from K1 Technologies, a partner of Wiseco, are made in China similar to Eagle rods and use the same ARP 2000 3/8” thread 1.600” length bolts. All connecting rod weights were checked on the small and big end using a precision connecting rod scale. After confirming weights, the rods were matched on the small and big end, and confirmed as a whole. All connecting rod were weight-matched to within 0.1 grams.

Polished and balanced crankshaft, Manley forged pistons, K1 Tech rods with bolts, and ACL performance rod bearings.

Piston ring gap verification is performed by installing a piston ring square to the bore and evenly lowering the ring below the deck surface. I made my own “tool” to do so. Some people use the piston itself, which works fine, but this is a faster positive way to do it.

Each connecting rod bolt is labeled using an engraver. Each bolt is measured and its length is recorded. During engine rebuild process connecting rod bolt length is recorded and compared to previous notes made. If connecting rod bolt length changes by more than 0.001” inch, then the bolt requires replacement. Connecting rod bolt is the most stressed component in the engine. Monitoring its size and condition can mean a difference between replacement of a $6 bolt or catastrophic engine failure.

Pistons installed

Connecting rod bolts tightened using a rod bolt stretch gauge. This is the most accurate method of tightening bolts. This method does not require any special lubricant. Stretch is a state that is measured via the dial indicator. This is more accurate than a torque method because torque method measures the friction in the thread. If improper lubricant is used then reading will not be accurate.

Cylinder 1 TDC is found using a bridge with a Mitutoyo dial indicator that reads in 0.0001” inch accuracy.

After TDC is established the piston dish volume can be measured. A clear acrylic plate is placed over the cylinder and a precision volume burette with colored alcohol fluid used to check piston dish volume.

ARP cylinder head stud kit installed into the block using ARP Ultra Torque moly lube.

Cosworth 87mm bore, 1.1mm thick headgasket installed

Cylinder head installed

Camshafts and timing chain guides installed. Camshaft lobes covered in Clevite assembly lubricant.

Comparison of standard and modified main studs

This is how close the modified stud comes to the upper oil pan. Unmodified stud does not allow the upper oil pan to seal the block.

Oil pump, oil pump chain, and tensioner guides installed.

Complete long block.

#5

Senior Member

Join Date: Dec 2008

Location: Floating around the AUDM

Posts: 3,837

Likes: 0

Received 0 Likes

on

0 Posts

Vehicle: X3 Sprint, S-Coupe Turbo

Nice attention to detail. I wonder how much hassle it would be to convert to a 4B11, because it does appear to be the stronger engine at this point.

#6

http://www.hyundaiaftermarket.org/images/vendor1.png

Thread Starter

Join Date: Jun 2011

Location: NJ

Posts: 198

Likes: 0

Received 0 Likes

on

0 Posts

Vehicle: Hyundai Genesis 2.0T

Original Poster on the other side had an update, so here it is:

UPDATE!

Crankshaft:

-48mm rod journals

-52mm main journals

-fully counter-weighed crank

-7 bolt flywheel mounting

-crankshaft weight: 38.3lb

Cylinder block:

-86mm cylinder bore

-56mm crankshaft main journal diameter

-2 bolt mains

-block deck height: 219.96mm

-main cap width(1,2,3,4,5 in mm): 21.70mm, 21.00mm, 20.00mm, 21.00mm, 21.10mm

-main bolt spacing: 96mm

-cylinder bore wall thickness: 9.0.8mm

-cylinder bores are siamese

-head bolt threads in block: M12x1.5

-head bolt thread depth in block: 60.66mm

-block weight: 46.0lb

Cylinder head:

-deck height: 128.45mm

-head weight: 31.7lb

-combustion chamber volume(stock): 48.5cc

Main Bearing Dimensions:

-width: 18mm

-ID: 52mm

-Housing size: 56mm(2.2061" inch)

-bearing thickness: 0.0795" inch at the thickest point

Intake valve dimensions:

-head OD: 35mm

-stem OD: 5.5mm

-total length: 113.18mm

-weight: 45.2g

-seat width: 1.5mm

Exhaust valve dimensions:

-head OD: 29mm

-stem OD: 5.5mm

-total length: 105.83mm

-weight: 41.9g

-seat width: 1.5mm

Shimless lifter buckets(intake and exhaust are same):

-lifter OD: 31.96mm

-lifter height: 28.5mm

-weight: 28.8g

Valve springs(intake and exhaust are same):

-spring OD: 23.96mm

-spring ID: 17.38

-wire diameter: 2.86mm

-free length: 46.38mm

-valve spring install height(intake): 35.29mm

-valve spring install height(exhaust): 35.83mm

-install height spring pressure(both intake and exhaust): 41lb

-weight: 30.5g

-retainer weight: 9.2g

-valve keepers(both): 1g

Valve spring pressures at different spring heights:

-40mm(20lb)

-35mm(40lb)

-30mm(65lb)

-25mm(93lb)

valve spring coil bind: 23mm

Pistons:

-compression height: 18.90mm

-weight: 344.5g

Piston pin:

-OD: 22mm

-length: 58mm

-weight: 121.9g

-piston pin c-clip weight(pair): 1.9g

Piston rings:

-top compression ring: 1.2mm thick, 7.0g weight

-second compression ring: 1.2mm thick, 7.3g weight

-oil ring pack: 2mm thick, 4.8g weight

Connecting rods:

-small end bushing bore: 22.04mm

-big end housing size: 51.58mm

-center-to-center length: 146mm

-weight: 584.2

I will add more info as it comes...

UPDATE!

Crankshaft:

-48mm rod journals

-52mm main journals

-fully counter-weighed crank

-7 bolt flywheel mounting

-crankshaft weight: 38.3lb

Cylinder block:

-86mm cylinder bore

-56mm crankshaft main journal diameter

-2 bolt mains

-block deck height: 219.96mm

-main cap width(1,2,3,4,5 in mm): 21.70mm, 21.00mm, 20.00mm, 21.00mm, 21.10mm

-main bolt spacing: 96mm

-cylinder bore wall thickness: 9.0.8mm

-cylinder bores are siamese

-head bolt threads in block: M12x1.5

-head bolt thread depth in block: 60.66mm

-block weight: 46.0lb

Cylinder head:

-deck height: 128.45mm

-head weight: 31.7lb

-combustion chamber volume(stock): 48.5cc

Main Bearing Dimensions:

-width: 18mm

-ID: 52mm

-Housing size: 56mm(2.2061" inch)

-bearing thickness: 0.0795" inch at the thickest point

Intake valve dimensions:

-head OD: 35mm

-stem OD: 5.5mm

-total length: 113.18mm

-weight: 45.2g

-seat width: 1.5mm

Exhaust valve dimensions:

-head OD: 29mm

-stem OD: 5.5mm

-total length: 105.83mm

-weight: 41.9g

-seat width: 1.5mm

Shimless lifter buckets(intake and exhaust are same):

-lifter OD: 31.96mm

-lifter height: 28.5mm

-weight: 28.8g

Valve springs(intake and exhaust are same):

-spring OD: 23.96mm

-spring ID: 17.38

-wire diameter: 2.86mm

-free length: 46.38mm

-valve spring install height(intake): 35.29mm

-valve spring install height(exhaust): 35.83mm

-install height spring pressure(both intake and exhaust): 41lb

-weight: 30.5g

-retainer weight: 9.2g

-valve keepers(both): 1g

Valve spring pressures at different spring heights:

-40mm(20lb)

-35mm(40lb)

-30mm(65lb)

-25mm(93lb)

valve spring coil bind: 23mm

Pistons:

-compression height: 18.90mm

-weight: 344.5g

Piston pin:

-OD: 22mm

-length: 58mm

-weight: 121.9g

-piston pin c-clip weight(pair): 1.9g

Piston rings:

-top compression ring: 1.2mm thick, 7.0g weight

-second compression ring: 1.2mm thick, 7.3g weight

-oil ring pack: 2mm thick, 4.8g weight

Connecting rods:

-small end bushing bore: 22.04mm

-big end housing size: 51.58mm

-center-to-center length: 146mm

-weight: 584.2

I will add more info as it comes...

#8

Member

Join Date: Dec 2011

Location: Southern Ontario

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

Vehicle: 2010 Genesis Coupe 3.8 - 1999 Hyundai Accent Hatch

Its not the OP's engine, just a post from GenCoupe. He goes by the forum name Pavel Engines. Here is a link to the builders blog PRE Tuning.

Good read for sure! This guy knows his stuff.

Good read for sure! This guy knows his stuff.